廣州市銀標(biāo)貿(mào)易有限公司

聯(lián)系人:賴(lài)先生

手機(jī):13922125860

固話:+86-20-23830796 23830403

傳真:+86-20-34637699

網(wǎng)址:www.yogaandcreativity.com

郵箱:laiqiangping2010@163.com

地址:廣州市番禺區(qū)鐘村鎮(zhèn)鐘榮路1號(hào)致業(yè)科技中心A棟3樓AS388#

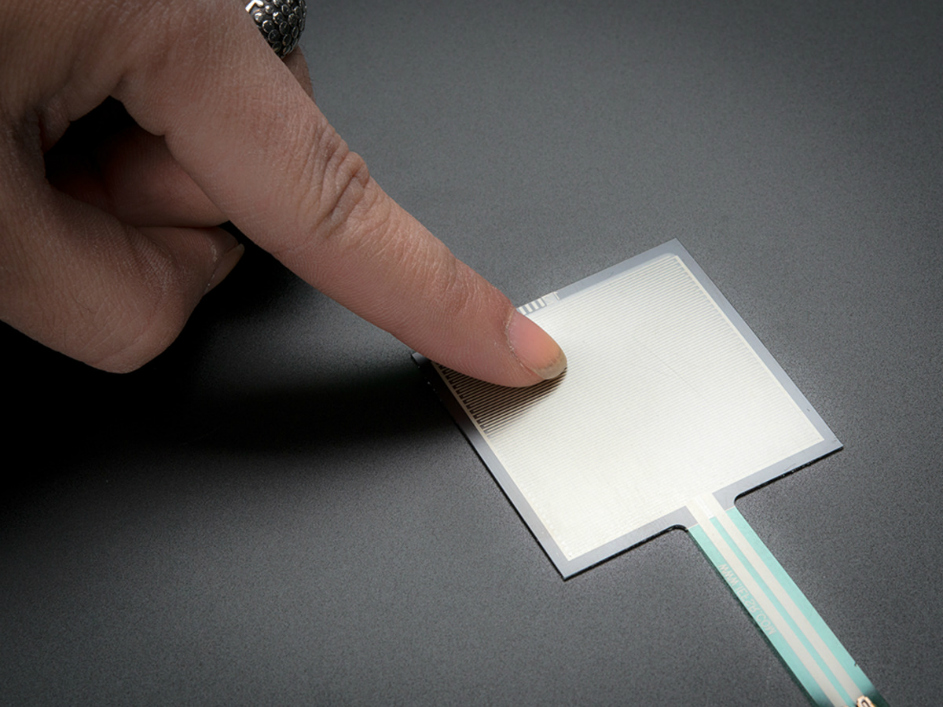

One of Canatu's touch sensors. Image: Matti Pirhonen/Canatu

Can you imagine touch-sensitive displays and surfaces for everything from wearable devices and home appliances to mobile devices and car dashboards? These are just some of the applications Finnish nanotechnology company Canatu sees for its touch-sensitive and transparent carbon nanobud (CNB) films, which can make almost any surface into a touchscreen.

以上資材如有需要請(qǐng)來(lái)電咨詢(xún):

Guang Zhou City Silver Well trading Co.,ltd

E-mail: laiqiangping2010@163.com

QQ: 598362644

+86-139-2212-5860

Canatu's films are stretchable, conductive, and formable, which means they can be used to add touch sensors to areas where physical buttons or controls would be difficult to place - on wristbands, for example. The sensors can be repeatedly flexed or bent across tight curves without any significant effect on their electrical conductivity, and the sensors can detect up to 10 touches simultaneously.

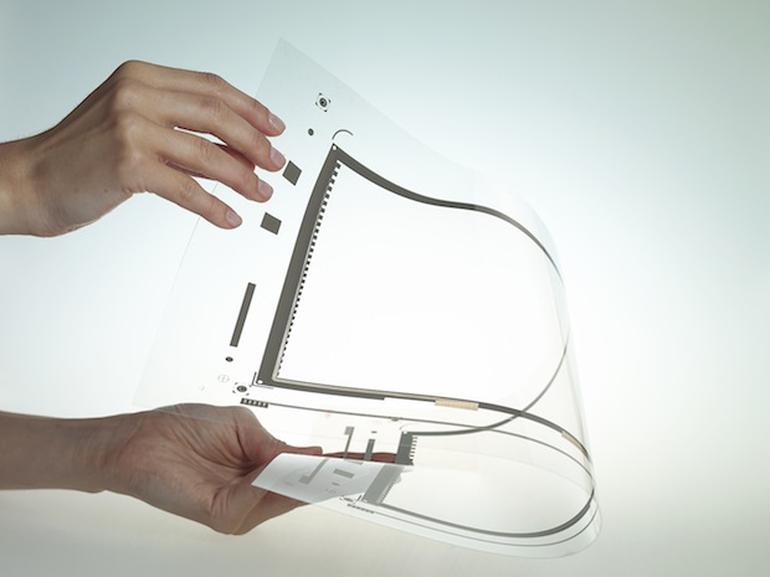

Now the company, which has 150 patents and released its first CNB film in 2013, is launching a touch-responsive film that can be stretched to cover virtually any 3D shape.

"The main benefit of our new CNB In-Mold film is the possibility of a 3D-shaped and curved design for touch. Never before has touch been accessible on almost any surface," says Ilkka Varjos, director of engineering at Canatu. "This gives product designers new design freedom and allows them to move beyond mechanical buttons."

Canatu has been developing its proprietary 'carbon nanobud' technology since the company was founded in 2004 as a spinoff from the Helsinki University of Technology (now the Aalto University).

Bends but won't break

The traditional method of making touch sensors is based on overlaying displays with sheets of indium tin oxide (ITO). While ITO conducts electricity well, its applications are limited. "Compared to CNB, ITO's properties are not as robust. ITO breaks when bent, CNB does not," explains Varjos.

ITO breaks because it's ceramic, so it can't flex or stretch. At its core, CNB is a hybrid of carbon nanotubes and fullerenes, both hollow carbon molecules.

According to Canatu, traditional nanotubes don't bond well to other molecules. However, nanobuds have useful properties displayed by both nanotubes and fullerenes, including the high thermal and electrical conductivity, high strength, and low density of traditional carbon nanotubes plus the high reactivity, low work function, and chemical functionalisability (meaning different functional chemical compounds can easily be incorporated to the molecule) of fullerenes.

"To our knowledge, no other carbon based material can reach the high transmission of 96 percent at 150 ohms/square sheet resistivity, whether traditional carbon nanotubes or graphene," Varjos adds.

CNB films have optical benefits too, according to Canatu, most notably low reflectance, high clarity, and a haze of less than 0.1 percent. That means the film can maintain outdoor readability and contrast with the underlying display. High contrast also enables low backlight power which can lead to long battery life, the holy grail for many device manufacturers.

First products in 2015

The material has already piqued the interest of electronics companies, against the background of many manufacturers tinkering with launching flexible and bending devices. There have been plenty of prototypes revealed over the last year, alongside some commercially available products with limited display flexibility like the LG G Flex, but widespread mass market products are yet to appear. However, Samsung announced a flexible display that can be bent in half in November and it's predicting that a consumer device with the new display will arrive by the end of 2015.

2015 will be important for Canatu too, as the company is getting close to seeing the first commercial applications of CNB films.

According to the company, more than 40 companies are currently working with its materials, testing them and preparing for mass production.

The first wearable devices using CNB films for touch sensors, such as fitness trackers, are scheduled to be released next spring - but the company won't say any more than that. The next step for the company will be in portable devices and gaming, and it estimates its films could be seen in car dashboards by 2016.

As a small company, employing 27 people across its headquarters in Finland and offices in China, Japan, and the US, Canatu is facing more demand than it can handle.

As a result, it's been scaling up its manufacturing capabilities from prototype quantities to a roll-to-roll manufacturing line for producing continuous rolls of CNB film. Canatu says this upgrade means it can soon produce enough film to cover hundreds of thousands of smartphone screens every month. Its capacity will be incrementally increased during 2015 with the addition of new modules to the production line.

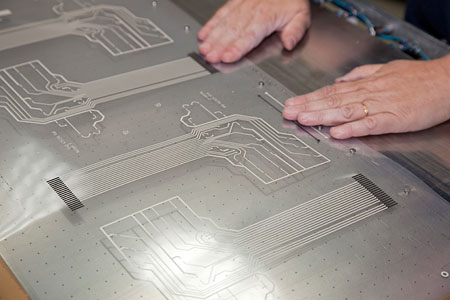

To combat manufacturing costs, Canatu uses direct dry printing, its own production method. DDP reduces production steps by allowing direct synthesis and placing of CNB films onto any substrate material (Canatu itself uses plastic substrate). The coated substrates can then be shipped to display manufacturers.

Fierce competition

Canatu is well aware of the competition in flexible and bendable touch sensors, but feels it is the first to offer a complete package. According to the company, alternative materials, like silver nanowire, break when stretched and lose their conductivity while nanobuds can be stretched up to 100 percent without a significant effect on electrical conductivity.

"Our products differ from metallic nanowires and metal meshes as our products are truly formable and stretchable," says Varjos. "Furthermore, CNB films do not suffer from the reflecting nature of the metallic competitors which results in visible touch sensor patterns and are not so readable in sunlight due to haze."

One current limitation of CNB is it cannot yet be used in screen sizes in excess of 15 inches as the conductivity of nanobuds isn't high enough to extend across the screens. But Canatu doesn't see this as a major problem at this stage and will release new products later this year.

"The market is driven by new design and the need for innovative solutions. Traditional flat surfaced devices are products of the past," Varjos concludes.